Activity areas

IAR S.A. – Activities / Competences

Development

- Design analysis, qualification / certification of new or upgraded aircrafts

- Avionics & equipment integration

- Ground and flight testing

Upgrading Programs

Customization

Manufacturing

- Structural sub-assemblies

- Electrical harnesses, distribution units and control boxes.

D Level Maintenance

- Airframe overhaul

- Labs for testing and repairs:

- Hydraulic equipment

- Fuel equipment

- Avionics

- Instruments

- Electrical equipment

I Level Maintenance

Structural Repairs

MRO Unit

- General Overhaul and Upgrades

- D Level Maintenance

- I Level Maintenance

- Structural repairs

Labs

- Hydraulic equipment

- Fuel equipment

- Avionics & instruments

- Electrical equipment

Manufacturing Workshops

- Airframes: metal sheet parts & assemblies

- Composite parts and assemblies

- Machining

- Welding, Metal to metal bonding

- Anti-corrosion protection, Chemical milling

- Heat treatment, Electro-erosion

- Electrical harnesses, control boxes

- Jigs and tools

Ground and Flight Tests

General overhaul hall:

- surface of : 5184 sqm

- useful height of: 12 m

- opening doors: 22m x 10m

- 3 rolling beam cranes: 3,2 t

Complete major overhaul operation:

- full disassembling and pickling

- corrosion inspection and removal

- detailed dimensional inspection in jigs

- structural repairs

- replacement of damaged parts

- overhaul of all systems and equipment

- assembling / fitting of airframe and systems

- Hydraulic equipment Lab

- Fuel equipment Lab

- Avionics & NAV / COMM Lab

- Instruments & Gyro Lab

- Electrical equipment Lab

Manufacturing Unit

- Sheet metal parts and subassemblies

- Composite parts and subassemblies

- Machining

- Welding

- Ducts and pipes

- Surface Treatments

- Painting

- Heat Treatment

- Electrical Wiring and Control panels

- Tools and jigs

Total surface for manufacturing : 20 770 sqm

Sheet metal parts and subassemblies workshop

Sheet metal parts and subassemblies workshop

Sheet metal parts and subassemblies workshop

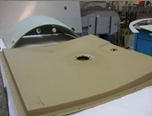

Composite Workshop

- Parts and assemblies made of: fiberglass reinforced polyster/epoxy resins, rubber and plastics

- Metal and non-metal , straight or curved honeycomb assemblies

- Metal-to-metal bonding

- Flexible ducts for ventilation

- Acrylic glass windows shaping

- Manufacturing or repair of the tail rotor blades

- Main rotor blades repairs

- Rubber fuel tanks production and repairs

Composite Workshop

Machining Workshop

Machining Workshop

Duct & Pipe Workshop

Manufacture of high and low pressure ducts and pipes for hydraulic, fuel, anemobarometic, ventilation and air-conditioning systems

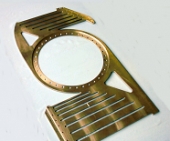

Wiring Workshop

Wiring Workshop

Wiring Workshop

Jigs and Tooling Workshop

Manufacture of specific devices, templates, checking or general tools necessary for production of the parts and subassemblies.

Wiring Workshop

CAPRIS 50 – Cable Printing and Identification System has been developed using ‘State of Art’ ultraviolet laser marking technology.

This technology offers means of printing high quality and truly permanent marks via a process designed to avoid damaging or affecting the integrity of the unsulation.

Wiring Workshop

MPT 5000 important features:

- Location of a failure

- Insulation testing as : dielectric withstand , insulation resistance

- Mass HIPOT

- Components testing : resistor, capacitors, transistors, diodes, inductors; shielded cables termination verification

Wiring Workshop